Investment Casting

SR Tech and Investment Casting process

SR Tech produces and imports Investment Casting products with KanBan Stock Management system.

We manufacture Stainless Steel, Carbon Steel and Specialty Alloy components in investment casting. We provide products complete with mechanical processing, surface finishing, heat and galvanic treatments. At our headquarters in Parma, in a warehouse, we manage over 1500m stock of reordering with KanBan system.

Investment Casting: What we do

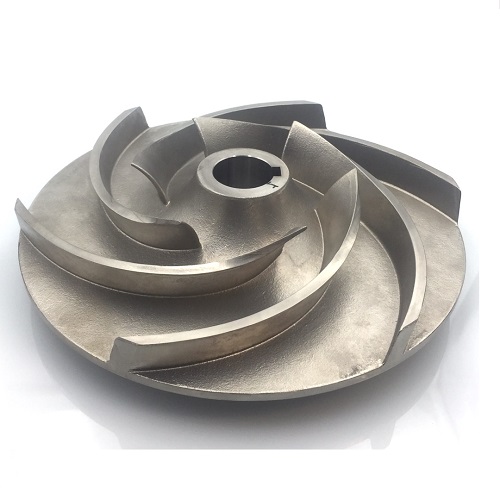

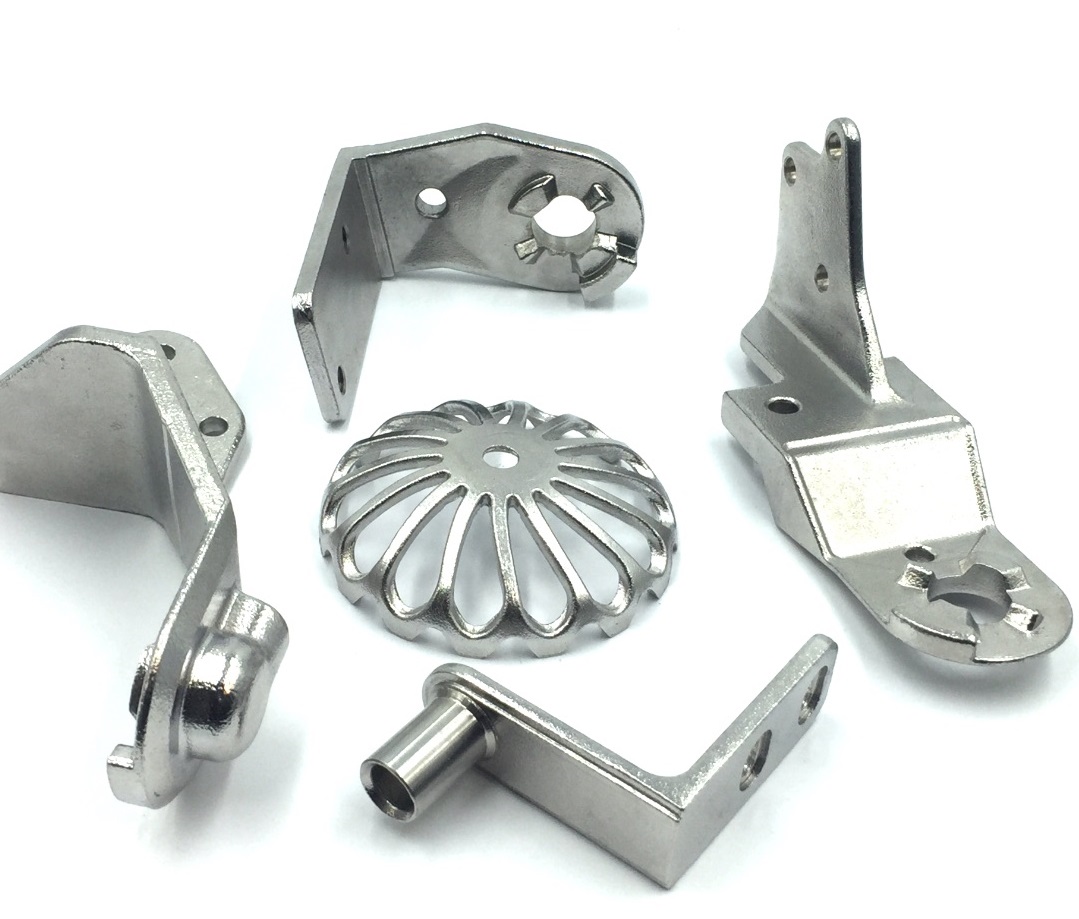

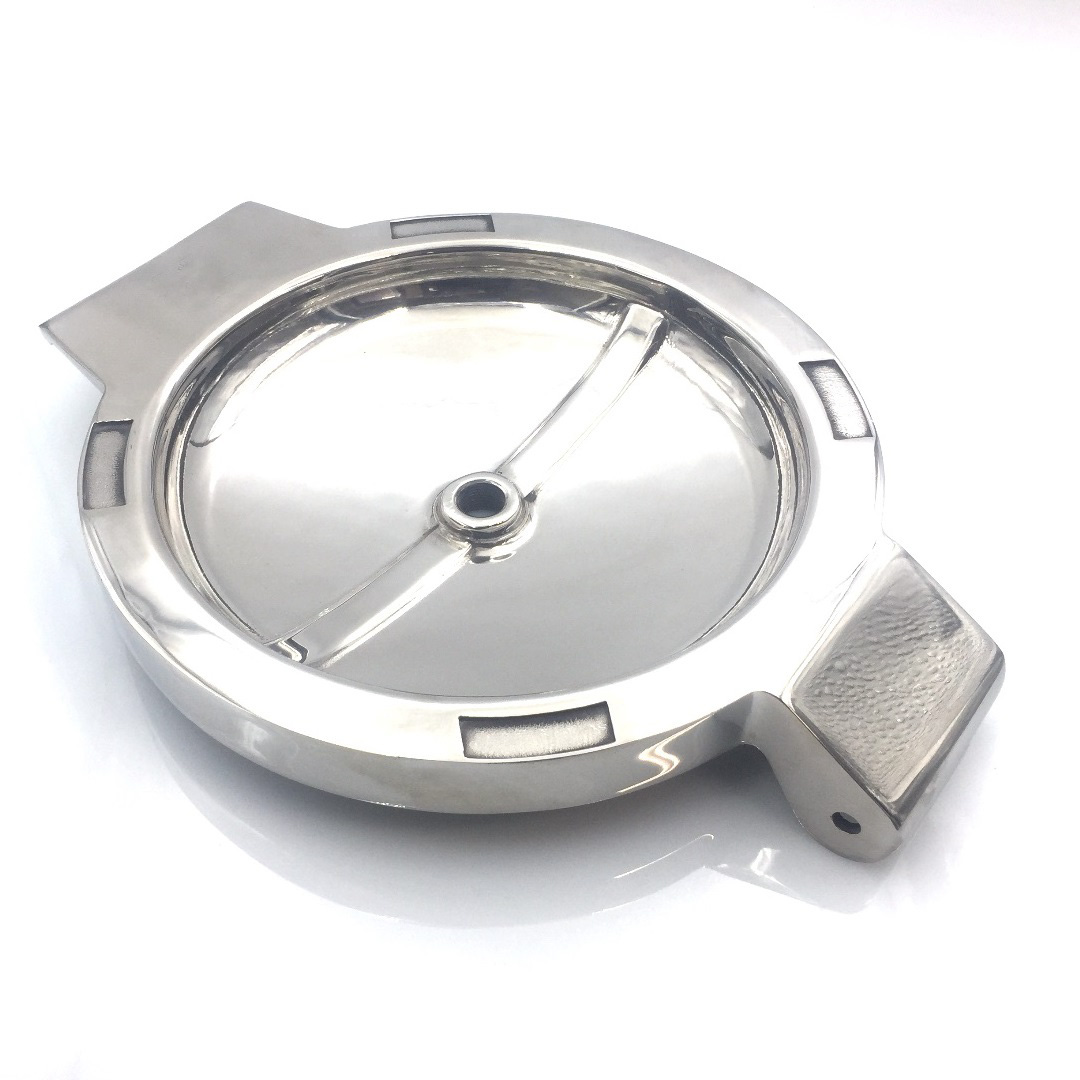

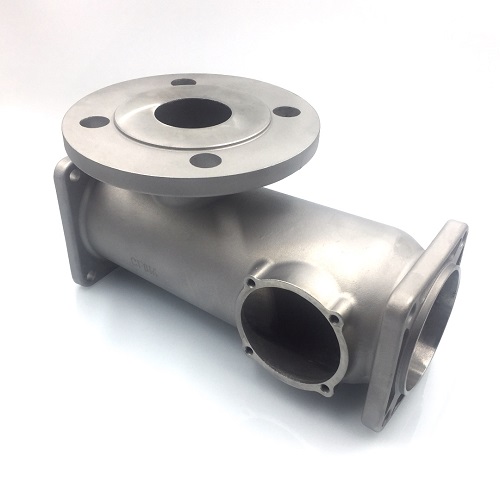

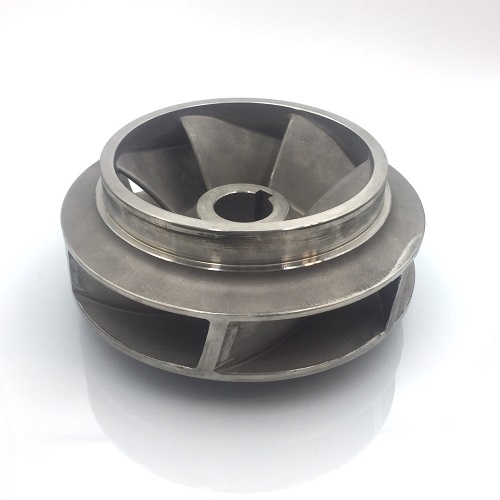

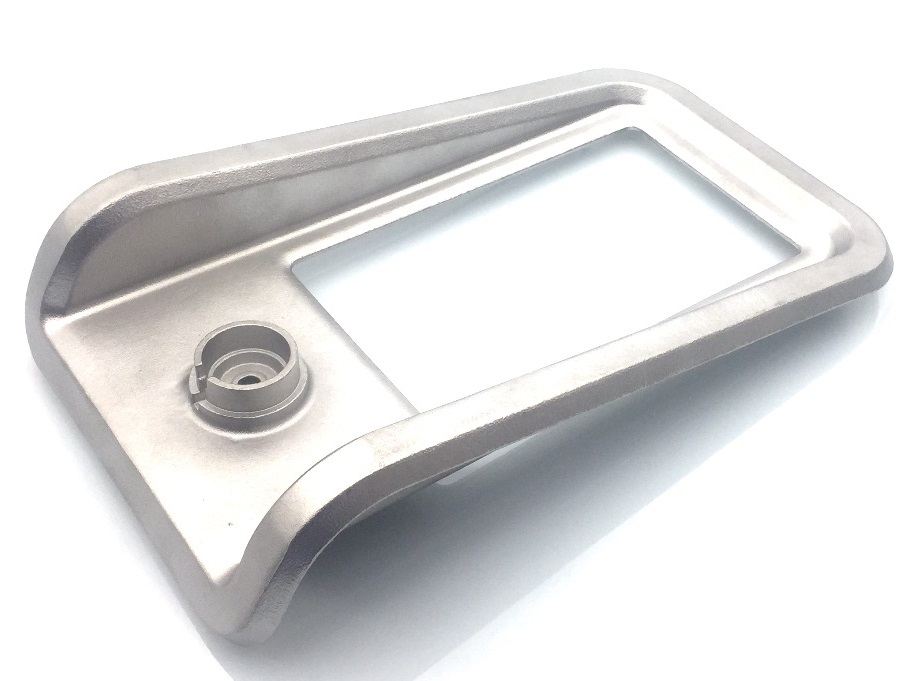

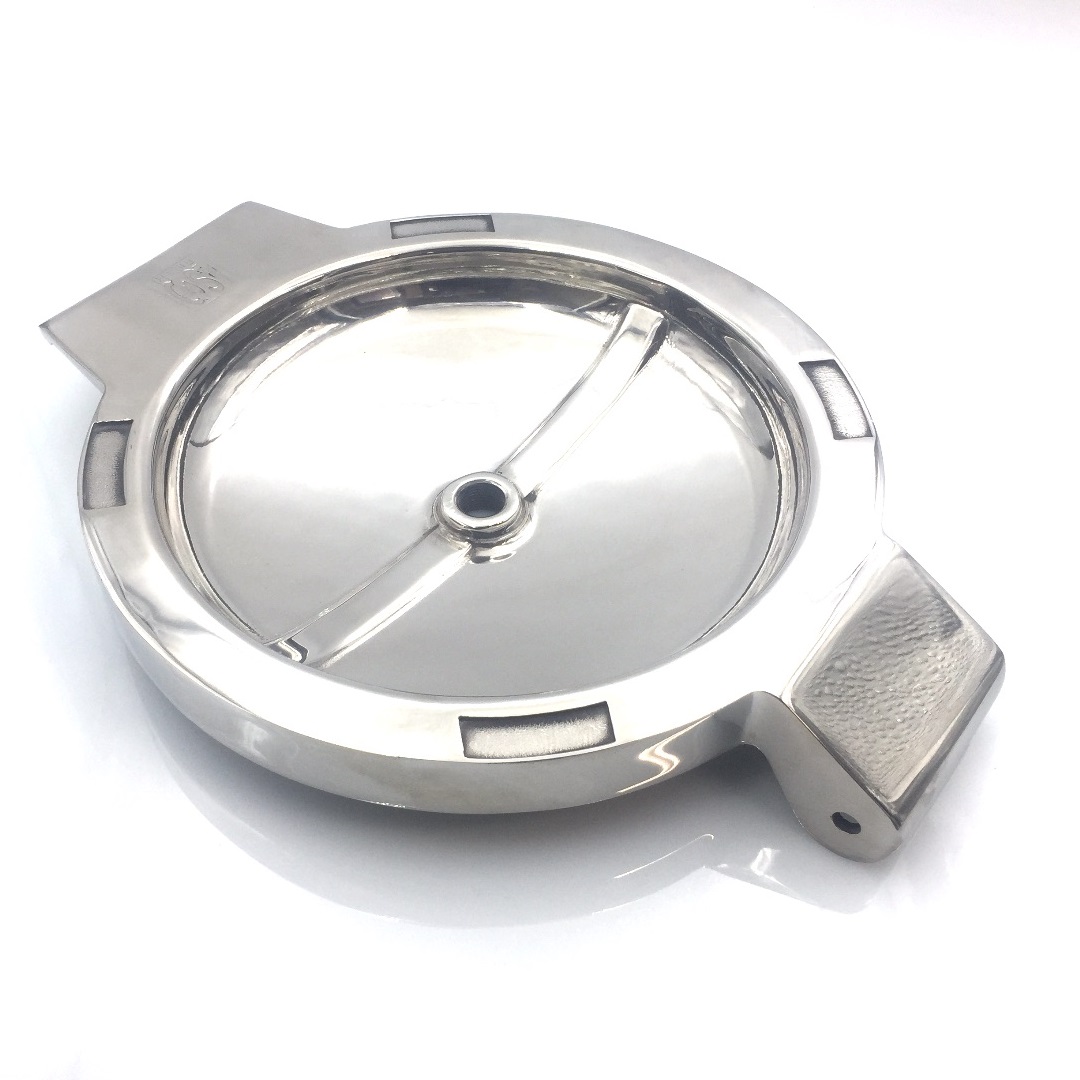

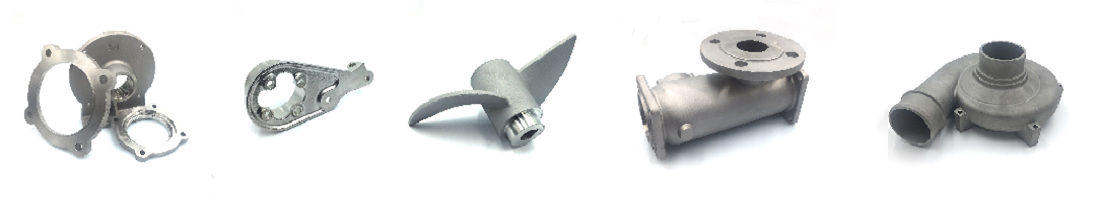

SR Tech manufactures and imports lost wax casting components from China with weights ranging from a few grams up to over 100 kg. We produce custom made items in Carbon Steel, Alloy Steel, Stainless Steel, Duplex and Superduplex.

The Lost Wax Casting process allows to produce objects with very complex geometric shapes, with high precision and surface finishes that often do not require additional machining.

The main fields of application of this technology cover sectors such as Oil and Gas, Furniture, Food and Beverage, Nautical, Automotive.

SR Tech, given the very nature of the production process, which requires medium-long production times, guarantees the continuity of supplies to its customers through the management of stocks with KanBan system in Parma, guaranteeing deliveries in just 5 working days.

Buying components in lost wax casting process without this kind of guarantee from the supplier means to put oneself in a situation of strong risk of stock shortage.

Investment Casting: Historical references

Investment Casting is a foundry process known since ancient times. Used in times long past almost exclusively for sculptural production, it was almost completely abandoned and then rediscovered during the Second World War for war purposes, and in the following 50’s for industrial production.

After the Second World War, Investment casting had a sudden development. Today, thanks to its versatility and dimensional precision, it covers various sectors such as: aeronautics and space, oil and gas, nautical, furniture, automotive, goldsmithing, medical, just to name a few.

The modern techniques used in the industrial field have had a continuous development. They passed from the technology called “Water Glass”, the only one initially available, to the most modern and reliable casting technology called “Silica Casting”, where Zirconium sands and silicate-based binders are the ingredients that allow to obtain much more performing ceramic shells. The Water Glass technology, despite being cheaper, has now been abandoned, mainly for 2 reasons:

– non-suitability for the melting of stainless steels

– low quality of the casting surface

– major porosity problems

In Italy, even if this technology was already known, it took hold only in the 50s, when it was imported from the United States.

In Russia the technological development went hand in hand with the American one, and from there the technology was exported to China around the end of the 50s.

Today the major producers are located in Asia, China and India, as the production process requires a lot of manpower, forcing up production costs in Western countries.

Investment Casting: The Production Process

The Lost Wax Casting Process is characterized by several steps. To know more about the production flow please refer to the video below.

Investment Casting: Products, Dimensions and Weightsi

With Lost Wax casting Process you can obtain products of variable dimensions, both in weight and size. Initially, this technology was only used for the production of small components, especially in the field of jewelry and in the dental field. Today, with lost wax casting technology, objects varying in weight from a few grams to over 100kg are produced. The dimensions of the items can reach volumes of 500mm*500*450mm; these dimensions are normally linked to the capacity of the presses used in the formation of waxes. However, considering that the single waxes can also be added together, the maximum dimensions can change greatly.

SR Tech produces components for different types of manufacturing industries. All products are made of steel, in various versions, stainless steel, alloyed, tempered, special. We do not produce Aluminium, Bronze or other non-ferrous alloys.

Investment Casting: KanBAn Stock Management

SR Tech imports castings from China. As it is easy to realize from the flow of the production process above, finished parts cannot be obtained in a short time; it takes at least 30 – 40 days to obtain the raw part with the Lost Wax Casting technology. At this point it is necessary to take into account any accessory machining, from CNC machining, to polishing, or finishing parts. So it is easy to reach at least 60 – 70 days before the part is ready to be shipped. Finally, the times of crossing by sea must be added to this lead time, and then we have to count the standard supply times of about 90 – 100 days. SR Tech has decided to activate at its headquarters in Parma the possibility to manage the stocks with KanBan system in security, completely eliminating the waiting time, guaranteeing the delivery of the products in 5 working days.

Ask for a Quote Now

For a free offer request pls send to us following informations:

- 3D drawings(step o iges)

- 2D drawings (dwg / dxf / pdf)

- Material Type

- Annual Forecast

write e-mail to:

commerciale@srtech.it

SR Tech srl

Via Segrè 11/a – 43122 Parma

phone: +39 0521 1556626

VAT: IT02630720346