MIM – Metal Injection Moulding

SR Tech and MIM- Metal Injection Molding

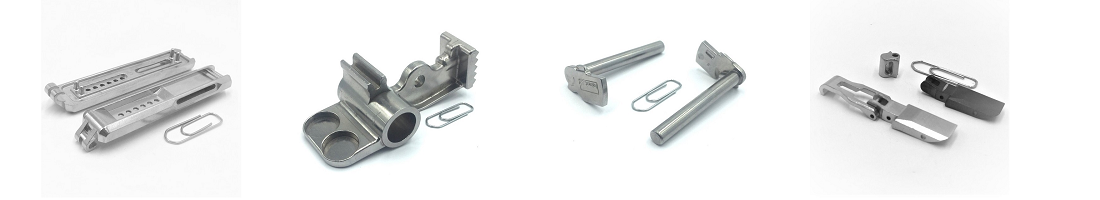

SR Tech produces and imports custom components in MIM process with inventory management with KanBan system.

The great advantage of MIM Moulding lies in the possibility to produce steel parts in large quantities and with excellent repeatability of the production cycle. Otherwise these parts, if produced in CNC, would have unsustainable costs. Unlike the classic technology of powder metallurgy (Sintering), the MIM allows to obtain much more complex geometries with a finished part density that reaches 97 – 98% of a product obtained from solid against an average of 70% of the sintered.

The sectors that most often make use of this technology are:

- Automotive

- Consumer Electronics

- Precision Mechanics

- Medical

- MIM – Metal Injection Molding

- Il Processo MIM

- Prodotti in MIM

- Tolleranze

- Confronto tra Tecnologie

MIM - Metal Injection Moulding: What we do

SR Tech manufactures and imports MIM components from China. With Metal Injection Moulding we produce articles made in carbon steel, alloy steel and stainless steel.

MIM - Metal Injection Moulding: Historical Background

The MIM Metal Injection Moulding Technology was developed in the early seventies for the Aeronautical sector.

This process is the combination of 2 traditional technologies such as Plastic Injection Moulding and Powder Sintering.

MIM - Metal Injection Moulding: The Production Process

The MIM process is characterized by several steps. To make it simple, you could say that MIM moulding is a combination of 2 different technologies. The injection moulding of plastics (first phase of the process) and the sintering of metal powders (second part of the process).

To learn more about this technology we invite you to discover the process in detail here.

MIM - Metal Injection Moulding: Products, Dimensions and Weights

MIM makes it possible to produce small but very precise metal objects. Feedstock injection moulding, due to its high viscosity, limits the filling of the mould to small surfaces. The mouldable objects can reach a weight of about 100 – 150g, but most of the production covers objects from 1 to 50g.

SR Tech produces MIM components for the automotive industry, the construction industry (window and door frames), pneumatics, Oil and Gas, the mechanical industry in general.

MIM - Metal Injection Moulding: tione Stock management at KanBan

SR Tech has decided to activate at its headquarters in Parma the possibility to manage stocks with KanBan system in security, completely eliminating waiting times. As for all the other technologies we deal with, also with MIM products we can guarantee your delivery in 5 working days.

Richiedi Preventivo Ora

Per richiedere un preventivo gratuito ci servono le seguenti informazioni:

- Disegno in 3D (step o iges)

- Disegno in 2D (dwg / dxf / pdf)

- Materiale

- Consumo annuno previsto

Il preventivo deve essere inviato a:

commerciale@srtech.it

Se invece volete maggiori informazioni sulla fattbilità, le lavorazioni accessorie o sulla gestione delle scorte a KanBan chiamateci senza impegno al:

0521/1556626

SR Tech srl

Via Segrè 11/a – 43122 Parma

PI: 02630720346